WET CHEMICAL FIRE SUPPRESSION SYSTEMS

INSPECTIONS, SALES, SERVICE, AND MAINTENANCE

WHAT ARE FIRE SUPPRESSION SYSTEMS?

A wet chemical fire suppression system is a specialized fire protection system designed to automatically detect and extinguish fires in commercial kitchens, restaurants, food trucks, and industrial cooking areas. These systems provide fast-acting, automatically or manually activated fire suppression for cooking environments where grease, cooking oil, and open flames pose constant hazards.

Wet chemical fire suppression systems use a potassium-based liquid agent that rapidly cools flames and reacts with burning cooking oils through saponification, forming a soapy foam barrier that smothers the fire and prevents re-ignition. These systems are permanently installed in commercial cooking areas and are designed to protect deep fryers, ranges, grills, and other cooking appliances.

A certified technician must inspect your fire suppression system every six months.

SEMI-ANNUAL FIRE SUPPRESSION SYSTEM INSPECTIONS

Regular fire suppression system inspections are required under the Ontario Fire Code and NFPA 17A to ensure restaurant and commercial kitchen suppression systems function properly in the event of a fire.

Semi-annual inspections are mandated to verify that all system components are operational, compliant, and capable of extinguishing grease fires before they spread.

WHAT’S INCLUDED IN A FIRE SUPPRESSION SYSTEM INSPECTION?

1. System Activation & Safety Features

- Test the automatic detection system

- Replace fusible links as required.

- Verify manual pull station functionality

- Inspect gas and electrical shutoff mechanisms

2. Nozzle Alignment & Piping Integrity

- Check that nozzles are correctly aligned to provide full coverage over cooking appliances.

- Inspect the piping system for grease buildup, blockages, leaks, or corrosion.

- Ensure nozzle seals/caps are in place to prevent grease and debris from obstructing the system.

3. Wet Chemical Agent & Cylinder Inspection

- Check chemical agent levels and the last hydro-test date.

- Verify cylinder(s) and/or cartridge(s) dates and pressures.

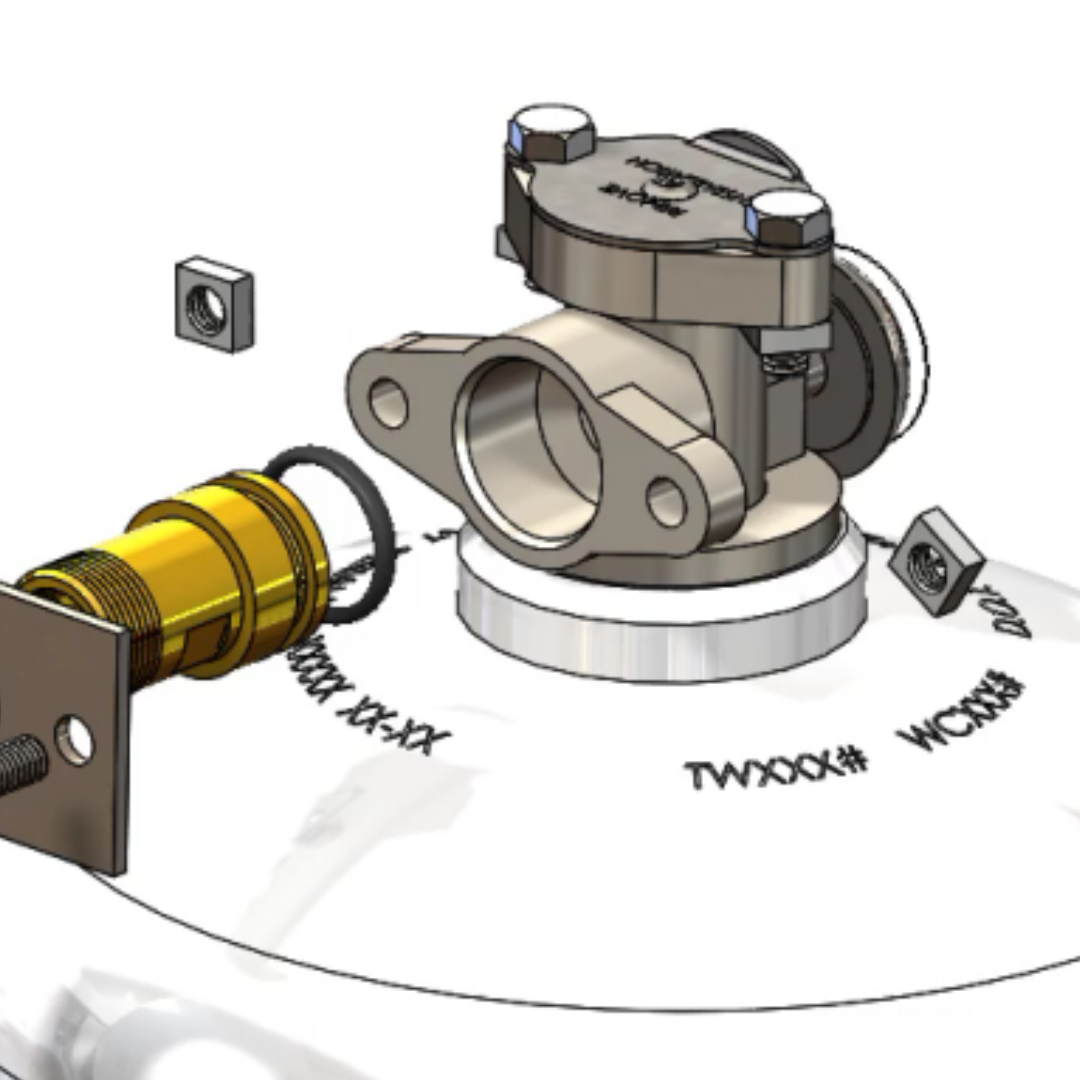

- Inspect system o-rings, seals, hoses, and valves.

4. Kitchen Hood & Ventilation System

- Inspect the hood, plenum, ductwork, and grease filters.

- Check that the suppression system integrates appropriately with exhaust fans and make-up air.

WHY FREQUENT INSPECTIONS ARE ESSENTIAL

Commercial kitchens are high-risk environments where grease, heat, flammable gases, and open flames create the perfect conditions for catastrophic fires.

Regular inspections ensure your fire suppression system remains fully operational by:

- Preventing grease buildup that can clog nozzles and reduce effectiveness.

- Verifying agent levels and pressure to suppress fires quickly and prevent re-ignition.

- Maintaining compliance with fire codes and insurance requirements, avoiding fines and coverage issues.

Without routine inspections, a malfunctioning system could fail in a fire, leading to significant property damage, business closures, or even loss of life.

SUPPRESSION AGENT & DISTRIBUTION

- Wet Chemical Agent – A potassium-based solution that reacts with burning grease.

- Agent Storage Tank/Cylinder – Holds the wet chemical suppression agent under pressure.

- Piping & Nozzles – Delivers the suppression agent.

DETECTION

- Heat Sensors/Fusible Links – These are temperature-sensitive devices that trigger the system when a fire is detected.

- Mechanical or Electric Detection Line – A network of cables or tubing that detects heat and activates the suppression system.

CONTROL & ACTIVATION

- Manual Pull Station – Allows staff to activate the system manually in case of an emergency.

- Automatic Release Mechanism – Engages the system when heat sensors detect a fire, releasing the suppression agent.

GAS AND/OR ELECTRICAL SHUTDOWN

- Gas Valve Shutoff – Cuts off the fuel supply to cooking equipment when the system activates.

- Electrical Disconnect – Shuts down power to cooking appliances to prevent reignition.

ALARM & MONITORING

- Alarm System Connection – Some systems integrate with fire alarm panels to alert staff and emergency services.

- Audible/Visual Alarms – Alerts occupants when the system is activated.

SUPPRESSION SYSTEM INSTALLATIONS

Opening a New Business? Congratulations!

A properly installed wet chemical fire suppression system is essential for commercial kitchens, restaurants, food trucks, and industrial cooking operations.

Adding and/or Moving Appliances?

If you’re rearranging your kitchen layout or adding new cooking equipment, your fire suppression system must be updated to ensure proper coverage and compliance.

- Repositioning nozzles to cover new appliances.

- Adjusting piping and for optimal fire protection.

Why Choose Regional Fire for Your System Installation?

Certified, professional fire suppression system installations to ensure your kitchen meets all safety and compliance standards. We work closely with fire departments and building inspectors to streamline approvals and get your business operational as quickly as possible.

- Custom system design tailored to your kitchen layout.

- UL 300-compliant systems from trusted manufacturers.

- Seamless integration with exhaust hoods, ductwork, and fuel shutoff systems.

- Fast, expert installation to minimize downtime.

- Comprehensive testing and certification to meet Ontario Fire Code and NFPA 17A standards.

FIRE SUPPRESSION SYSTEM UPGRADES & RETROFITTING

UL 300 is the current safety standard that requires fire suppression systems to be tested and designed specifically for modern high-efficiency cooking equipment, which burns hotter and produces more grease than older appliances.

Non-compliant systems may fail to extinguish fires properly, leading to dangerous flare-ups and other risks.

Upgrade & Retrofit Services

- Convert older systems to UL 300 compliance.

- Reconfigure nozzles and agent distribution.

- Install additional suppression nozzles.

- Replace outdated wet chemical agents that may not meet modern fire code requirements.

Not sure if your system is UL 300 compliant? Contact us today for a free assessment and compliance check!

Help! My Fire Suppression System Went Off

If your kitchen fire suppression system discharged, whether due to a fire or an accidental activation, your business is now unprotected and non-compliant until the system is recharged and reset by a certified technician.

Don’t panic—we’re here to save the day with fast, professional fire suppression system recharging!

What to Do if Your Fire Suppression System Discharged:

- Call us immediately for fast system recharging—we provide same-day service to get you up and running.

- Do NOT attempt to reset the system yourself—this can cause further issues and fail a fire inspection.

- Schedule an inspection to ensure everything is in working order before reopening your kitchen.

24/7 Fire Suppression System Services

We provide 24/7 emergency and after hours services to quickly diagnose and repair issues, ensuring your kitchen stays protected with minimal downtime.

We Fix Common Fire Suppression System Issues, Including:

- Emergency system recharges after an activation or accidental discharge.

- Blocked or misaligned nozzles that reduce fire suppression coverage.

- Faulty fusible links or manual activation failures preventing system operation.

- Gas shutoff malfunctions stopping appliances from being used after a system discharge.

- After-hours system upgrades and installations to keep your business running smoothly.

Our certified technicians work fast to get your suppression system in service so you can stay compliant.

Who Needs Suppression System Inspections?

What You Receive After the Inspection

After completing your suppression system inspection, we provide detailed digital reports and compliance documentation to ensure your business stays up to code. Our reports offer a breakdown of your system’s condition and maintenance needs.

Our technicians document findings in real time using phones or tablets and can email your inspection report directly to the appropriate contact.

1. Detailed Digital Inspection Reports

-

A full breakdown of your suppression system’s status, including nozzle placement, pressure levels, and overall condition.

-

Identification of any non-compliant components or maintenance needs.

-

Deficiency notes detailing corrective actions.

2. On-Site Maintenance & Service Capabilities

Most of the time, our technicians can fix minor deficiencies on-site, such as replacing fusible links, adjusting/replacing nozzles, or swapping out damaged components. However, more extensive services like hydrostatic cylinder testing, full system recharges, or major repairs may require a follow-up visit. If additional maintenance is needed, we will work with you to schedule a convenient service appointment.

3. Certification of Compliance Upon Request

-

Official documentation confirming that your suppression system meets all required fire codes and safety standards.

-

Certificates available for fire inspectors, insurance providers, and internal safety records.

-

Digital copies sent via email for seamless record-keeping and accessibility.

Hassle-Free Compliance & Streamlined Documentation

Our digital reporting system eliminates paperwork delays and ensures real-time updates on your suppression system’s compliance status. Whether you need a one-time inspection or scheduled maintenance, we make the process simple, efficient, and stress-free.

Stay compliant and protect your business—schedule your suppression system inspection with Regional Fire today!